Schrader and Presta valves explained

Modern bicycle tires are pneumatic tires, meaning that they are inflated with air to a moderate or high pressure. In almost all cases today, bicycle tires either use innertubes (an internal air bladder), or are "tubeless" in which case the tire is inflated directly with no internal bladder. In either case, the tire (or innertube) will have a valve through which it is inflated. There are two distinct types of valves in use, and each works differently. The two types of valves are known as "Schrader" and "Presta". Schrader valves are sometimes called "American valves", and Presta valves are sometimes called "French valves". Schrader valves are the same valve that are found on all automobile tires, and they are also found on bicycle innertubes. Presta valves are typically only used on bicycle innertubes or tubeless wheels.

Schrader and Presta valves each use a different fitting for the "air chuck" that connects to the valve for inflation. Some bicycle pumps have an air chuck that is capable of fitting either type of valve, and some have a double-headed air chuck with a Presta fitting on one side, and a Schrader fitting on the other side. Many pumps have an air chuck that is capable of fitting one or the other, but not both. The air compressors found at gasoline stations have an air chuck that fits Schrader valves, and an adapter is required to go in between if a tire using a Presta valve is to be inflated using a gasoline station air compressor.

| NOTE: Generally speaking, inflating bicycle tires using gasoline station or other commercial air compressors is not recommended as it is very easy to accidentally over-inflate the bicycle tire to a harmful pressure using such compressors. |

Physical differences

The most obvious difference between Schrader and Presta valves is the diameter of the valve stem. Presta valves have a noticeably narrower valve stem at 6 mm wide, compared to Schrader valves which are 8 mm wide. Presta valves come in various valve stem lengths commonly ranging from 48 mm to 80 mm whereas Schrader valves are generally limited to one standard valve stem length.

Presta valves have a small captive nut on the very top that must be unscrewed to open the valve (for inflation or deflation), and must be screwed shut to close the valve. Once inflated, the air pressure inside the innertube (or tubeless tire) holds the Presta valve shut. Schrader valves have no such manual open and close mechanism, and instead use a spring-loaded poppet valve, which when depressed ag against the spring opens the valve for inflation or deflation, and when not depressed, the internal spring closes the valve.

|  |  |

| Presta valve with (optional) valve cap installed | Presta valve with the valve in the open condition | Presta valve with the valve in the closed condition |

|  |

| Schrader valve with cap installed | Schrader valve with cap removed |

Operational differences

Inflating innertubes and/or tubeless tires equipped with Presta and Schrader valves is similar, but has noticeable differences that must be observed.

Presta valve inflation procedure:

- Remove (unscrew) the valve cap (if present)

- Fully unscrew the valve's captive top nut to open the valve

- Attach air chuck from pump (or attach CO2 inflator)

- Inflate to desired air pressure

- Remove air chuck from pump (or detach CO2 inflator)

- Fully screw closed the captive top nut to close the valve

- Replace (screw on) the valve cap (if present)

Presta valve deflation procedure:

- Remove (unscrew) the valve cap (if present)

- Fully unscrew the valve's captive top nut to open the valve

- Manually depress the valve straight downward by pressing downward on the very top

- Deflate to desired air pressure

- Fully screw closed the captive top nut to close the valve

- Replace (screw on) the valve cap (if present)

Schrader valve inflation procedure:

- Remove (unscrew) the valve cap (if not present, obtain a replacement at first opportunity)

- Attach air chuck from pump (or attach CO2 inflator)

- Inflate to desired air pressure

- Remove air chuck from pump (or detach CO2inflator)

- Replace (screw on) the valve cap (if not present, obtain a replacement at first opportunity)

Schrader valve deflation procedure:

- Remove (unscrew) the valve cap (if not present, obtain a replacement at first opportunity

- Using a pointed object or tool, manually depress the valve's center button located in the center of the valve stem opening

- Deflate to desired air pressure

- Replace (screw on) the valve cap (if not present, obtain a replacement at first opportunity)

Valve caps

Both Schrader and Presta valves come with a valve cap that screws onto the valve to keep out dirt and debris. A valve cap should always be used on Schrader valves to keep debris or dirt from entering the valve, but depending on personal preference, it is acceptable (but not recommended) to leave the valve cap off a Presta valve. That is because a Presta valve's design includes a closure that screws down that closes off the inner-workings of the valve core contained in the valve stem. If a rider chooses not to use a valve cap on a Presta valve, it is still important to leave the valve cap on spare innertubes so that when rolled up for storage, the pointed end of the Presta valve's mechanism will not damage the innertube.

Stem length

Innertubes have a "valve stem" (a hollow tube, usually threaded) as an integral part of the innertube, and the actual valve is contained within the valve stem at the top of the stem. Innertubes using Schrader valves typically only come with one choice of valve stem length. However, innertubes using Presta valves come in a variety of stem lengths. When purchasing replacement innertubes with Presta valves, it is very important to purchase innertubes with the correct valve stem length. A Presta valve innertube with a valve stem that is longer than actually needed is not ideal, but it is acceptable to use. But a Presta valve innertube with a valve stem that is too short will not be usable. This is because many wheels have different height profiles, requiring varying length valve stems in order for the valve to extend up out of the wheel rim with enough clearance to attach an air chuck. Many wheels with high profiles are referred to as "aero wheels" or "deep dish" wheels.

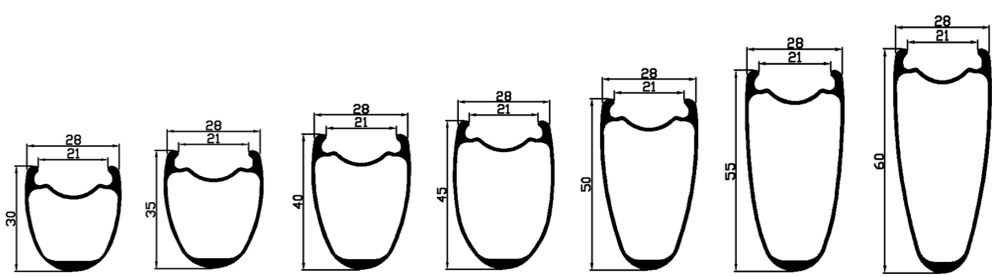

|

| Above are pictured various wheel rim cross-sectional profiles with dimensions shown in millimeters (mm). An innertube with a valve stem length of 48mm will work fine with the first two pictured profiles (from left to right), but would NOT work with the last four profiles (from left to right). An innertube with a valve stem length of 80mm will work in all of the above wheels (but would not be ideal in the first four, as the extra valve stem height would cause some slight aerodynamic drag). |

| TIP: It is all too common for riders to experience a flat tire while riding, and remove their spare innertube from their under-saddle bag only to find that the spare tube has a valve stem too short to be used with their wheel! This is especially true for riders that use the same under-saddle bag for multiple bicycles, and may have one bicycle with wheels that have a taller cross-sectional profile than their other bicycles. Such riders should opt to carry a spare tube with the longest valve stem needed to accomodate the tallest wheel profile of the bikes they ride. |

One of the primary advantages of Presta valves is found in its smaller diameter valve stem. That allows for a smaller valve stem hole in the wheel rim, which adds to the rim's strength. It is possible to install Presta valve innertubes in wheels intended for Schrader valve innertubes. Doing so requires adding an inexpensive bushing to allow for the smaller diameter Presta valve's stem to fit in the wheel's larger hole intended for a Schrader valve. Such adapters are available from Crossroads Cycling Company and Cabarrus Cycling Company.

© by Todd M. Smith 2022, 2023 All rights reserved